Introduction

Wedge gate valves are integral components in various industrial applications, known for their reliable performance and versatility. They are particularly valued for their ability to provide tight shut-off, low-pressure drop, and durability. In this blog, we will delve into the benefits of wedge gate valves, exploring their design, functionality, and the advantages they bring to different industries.

Understanding Wedge Gate Valves

Design and Functionality

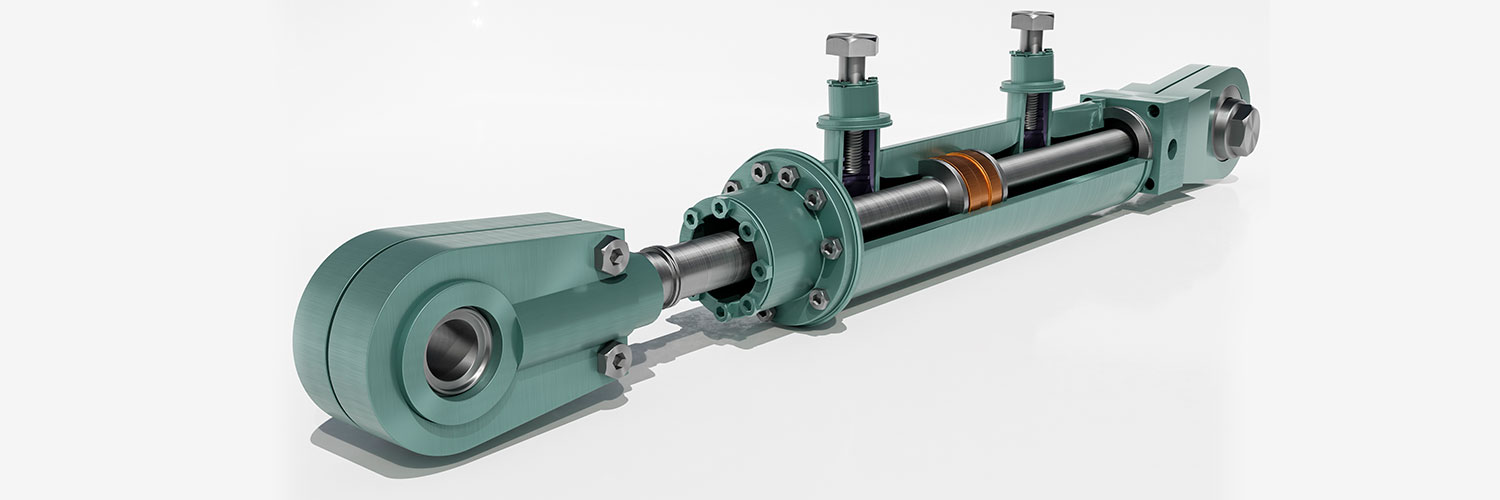

Wedge gate valves are named after their wedge-shaped disc, which moves up and down to control the flow of fluid through the valve. The key components of a wedge gate valve include the body, bonnet, stem, gate (disc), and seats. The valve operates by raising or lowering the gate, which fits snugly into the valve seats to stop the flow of fluid.

The wedge-shaped gate can be solid or flexible. A solid wedge offers robust performance in various conditions, while a flexible wedge can adapt to changes in temperature and pressure, reducing the likelihood of thermal binding.

Types of Wedge Gate Valves

There are several types of wedge gate valves, each designed for specific applications and operating conditions:

- Solid Wedge Gate Valves: These are the most common type, offering simplicity and strength for general-purpose applications.

- Flexible Wedge Gate Valves: Designed to handle varying temperatures and pressures, these valves prevent binding and ensure a tight seal.

- Split Wedge Gate Valves: These consist of two separate discs, allowing for better alignment and sealing in high-pressure applications.

Benefits of Wedge Gate Valves

- Reliable Shut-Off

One of the primary benefits of wedge gate valves is their ability to provide a reliable shut-off. The wedge-shaped disc ensures a tight seal against the seats, effectively stopping the flow of fluid. This feature is crucial in applications where preventing leaks is essential, such as in the oil and gas, chemical, and power generation industries.

- Low Pressure Drop

Wedge gate valves are designed to offer minimal resistance to fluid flow when fully open. The straight-through flow path reduces turbulence and pressure drop, making them highly efficient. This characteristic is particularly beneficial in applications where maintaining consistent flow and pressure is critical.

- Durability and Longevity

The robust construction of wedge gate valves ensures durability and longevity, even in demanding environments. Made from high-quality materials such as stainless steel, carbon steel, and alloy steel, these valves can withstand high pressures, temperatures, and corrosive conditions. This durability translates into lower maintenance costs and extended service life.

- Versatility

Wedge gate valves are versatile and can be used in a wide range of applications. They are suitable for both on/off and throttling services, making them ideal for various industries, including oil and gas, water treatment, power generation, and chemical processing. Their ability to handle different types of fluids, including liquids, gases, and slurries, further enhances their versatility.

- Bi-Directional Flow

Unlike some valve types that are designed for unidirectional flow, wedge gate valves can handle bi-directional flow. This feature simplifies pipeline design and allows for more flexible installation options, making them a preferred choice in many industrial systems.

- Ease of Operation

Wedge gate valves are relatively easy to operate. They can be actuated manually or equipped with electric, pneumatic, or hydraulic actuators for remote operation. The straightforward design of these valves ensures smooth and reliable operation, reducing the risk of operational issues.

- Cost-Effectiveness

The long service life and low maintenance requirements of wedge gate valves contribute to their cost-effectiveness. Although the initial investment might be higher compared to some other valve types, the overall cost of ownership is lower due to reduced downtime, maintenance, and replacement costs.

Applications of Wedge Gate Valves

Oil and Gas Industry

In the oil and gas industry, wedge gate valves are used in a variety of applications, including upstream, midstream, and downstream operations. They are essential for controlling the flow of crude oil, natural gas, and refined products. Their reliable shut-off capability and durability make them ideal for high-pressure and high-temperature environments.

Water Treatment

Wedge gate valves play a crucial role in water treatment plants, where they are used to control the flow of water and other treatment chemicals. Their low-pressure drop and bi-directional flow capabilities ensure efficient operation and optimal performance in water distribution and wastewater management systems.

Power Generation

In power generation plants, wedge gate valves are used to regulate the flow of steam, water, and other fluids. They are vital components in both conventional and renewable energy systems, providing reliable shut-off and flow control in high-pressure and high-temperature conditions.

Chemical Processing

The chemical processing industry relies on wedge gate valves for handling various chemicals, including corrosive and hazardous substances. Their robust construction and resistance to corrosion make them suitable for use in aggressive chemical environments. Additionally, their ability to provide a tight shut-off ensures safety and prevents leaks.

Mining

In the mining industry, wedge gate valves are used to control the flow of slurries, abrasive fluids, and other challenging materials. Their durability and ability to handle harsh conditions make them indispensable in mining operations, where reliable performance is crucial to maintaining productivity and safety.

Choosing the Right Wedge Gate Valve

Material Selection

Choosing the right material for a wedge gate valve is essential to ensure compatibility with the fluid and operating conditions. Common materials include:

- Stainless Steel: Offers excellent corrosion resistance and durability, suitable for a wide range of applications.

- Carbon Steel: Provides strength and toughness, ideal for high-pressure and high-temperature environments.

- Alloy Steel: Combines strength and corrosion resistance, suitable for aggressive chemical and high-temperature applications.

Valve Size and Pressure Rating

Selecting the appropriate valve size and pressure rating is crucial for ensuring optimal performance and safety. The valve size should match the pipeline diameter, and the pressure rating should be compatible with the operating pressure of the system.

Actuation Method

Wedge gate valves can be operated manually or equipped with actuators for remote operation. The choice of actuation method depends on the specific application requirements and the need for automation. Electric, pneumatic, and hydraulic actuators offer different advantages and should be selected based on factors such as response time, power source availability, and control requirements.

Industry Standards and Certifications

Ensuring that the selected wedge gate valve meets industry standards and certifications is essential for guaranteeing quality and reliability. Common standards include API (American Petroleum Institute), ASME (American Society of Mechanical Engineers), and ISO (International Organization for Standardization). Compliance with these standards ensures that the valve is designed and manufactured to meet stringent quality and performance criteria.

Maintenance and Troubleshooting

Routine Maintenance

Regular maintenance is essential to ensure the longevity and optimal performance of wedge gate valves. Routine maintenance tasks include:

- Inspection: Regularly inspecting the valve for signs of wear, corrosion, or damage.

- Lubrication: Applying appropriate lubricants to the valve stem and other moving parts to ensure smooth operation.

- Cleaning: Removing any debris or build-up from the valve body and seats to prevent blockages and ensure a tight seal.

Troubleshooting Common Issues

Understanding common issues that can affect wedge gate valves and knowing how to troubleshoot them is crucial for maintaining reliable operation. Some common issues include:

- Leakage: Leakage can occur due to damaged seals, worn seats, or improper installation. Inspecting and replacing damaged components can resolve this issue.

- Sticking: Sticking can result from corrosion, debris build-up, or inadequate lubrication. Cleaning and lubricating the valve can improve operation.

- Excessive Wear: Excessive wear can occur due to abrasive fluids or high operating pressures. Using appropriate materials and regular maintenance can mitigate this issue.

Conclusion

Wedge gate valves offer numerous benefits, including reliable shut-off, low-pressure drop, durability, and versatility. Their ability to handle bi-directional flow, ease of operation, and cost-effectiveness make them indispensable in various industries, including oil and gas, water treatment, power generation, chemical processing, and mining.

At Steelstrong, we take pride in providing high-quality wedge gate valves designed to meet the demanding requirements of modern industrial applications. Our valves are manufactured to the highest standards, ensuring exceptional performance, reliability, and longevity. With a commitment to innovation and excellence, Steelstrong continues to be a trusted partner for industries worldwide, delivering valve solutions that drive efficiency and safety.