Introduction

The foundation of contemporary society lies in natural gas distribution networks, which supply homes and businesses with efficient and clean energy. Natural gas distribution networks must be monitored appropriately to protect the environment and the general population. The valve is among the most crucial parts of a natural gas distribution network. In the case of a leak or rupture, valves isolate specific network segments and regulate gas flow. One kind of valve frequently found in natural gas distribution networks is the forged valve.

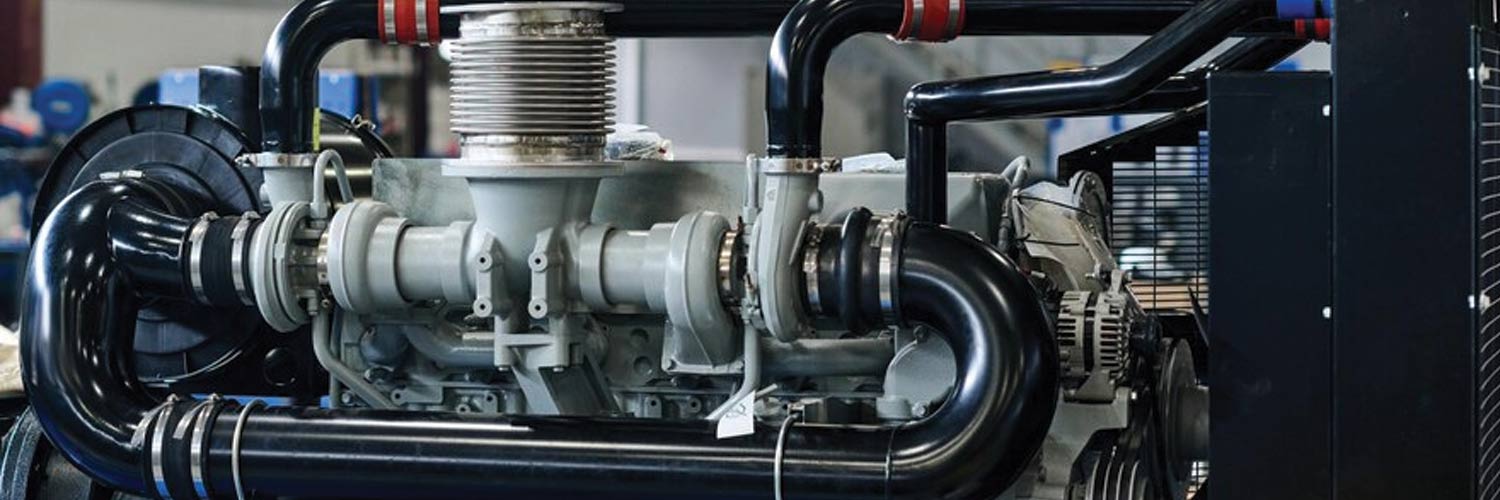

Forged Valves: The Unsung Heroes of Safe Natural Gas Distribution

In contrast to cast valves, forged valves are produced using a technique that includes forming solid metal parts at high temperatures and pressures. This process has valves with improved mechanical characteristics, including increased sturdiness, toughness, and resistance to high-pressure situations. Forged valves are recommended in situations where dependability and safety are crucial, like in natural gas distribution, because of these characteristics.

Safety

In the natural gas sector, safety comes first. Natural gas distribution network safety is a complex issue with environmental and operational factors. Forged valves are a vital component in guaranteeing the security of natural gas distribution networks. Because forged valves offer exact control over gas flow and pressure, they greatly enhance operating safety. Their sturdy design lowers the possibility of valve failure, which lessens the chance of leaks, ruptures, or other disastrous occurrences. Forged valves are also made to endure harsh temperatures and corrosive conditions, which increases their dependability under the demanding circumstances of natural gas distribution systems.

Forged valves are not only naturally solid and durable, but they also have several safety features. Among these characteristics are:

Safety locks: Safety locks guard against unintentional valve opening.

Pressure relief valves: These valves keep the network’s pressure from rising to dangerously high levels.

Indicators: Indicators indicate the state of an open or closed valve.

Compliance

For natural gas distribution networks, compliance is a crucial factor in addition to safety. Compliance with the standards and regulations of the industry is non-negotiable.

Forged valves must adhere to industry requirements to be deemed trustworthy and safe. Organisations like the American National Standards Institute (ANSI) and the American Society of Mechanical Engineers (ASME) develop these standards. Regarding natural gas distribution, adherence to industry norms and laws is mandatory. Regulatory authorities impose tight regulations to protect the environment and public health. Because forged valves are designed and tested to meet or surpass these requirements, operators and regulators may be assured of the distribution network’s dependability and security. Compliance with these standards is also essential to achieving the required certifications and reassuring stakeholders that the natural gas distribution system is constructed and maintained with the highest quality and safety requirements.

FAQ about Forged Valves in Natural Gas Distribution Networks: Safety and Compliance

Q1: Are there specific considerations for selecting forged valves based on the characteristics of the natural gas being transported?

Factors like the composition of the transferred natural gas, temperature, and pressure should be considered when choosing forged valves. For best performance and safety, valve specifications should match the unique needs of the gas distribution network. Making suitable valve options requires speaking with professionals and following industry standards’ recommendations.

Q2: What maintenance practices are recommended for forged valves in natural gas distribution networks?

Regular maintenance of forged valves in gas distribution networks is necessary for optimum utilisation. Maintenance practices cover routine examinations, lubricating moving parts, and changing worn-out parts. As soon as there are any indications of corrosion, leakage, or unusual wear, they should be fixed. It is crucial to adhere to the manufacturer’s maintenance recommendations and industry best practices to guarantee the forged valves’ continued dependability and safety.

Q3: Are there advancements or emerging technologies in forged valve design for natural gas distribution networks?

Developments in materials, coatings, and design methods are continuous in forged valves. These developments could improve valves’ longevity, effectiveness, and performance in networks that distribute natural gas. Maintaining awareness of these developments and taking them into account when choosing and replacing forged valves can help increase the gas distribution system’s overall safety and dependability.

Q4: Can forged valves be used for underground and aboveground natural gas distribution systems?

Natural gas distribution systems above and below ground can use forged valves. The selection of a valve is contingent upon the particular project specifications and surrounding circumstances. Forged valves are robust and long-lasting, making them suitable for various uses in the infrastructure supporting natural gas distribution.

Q5. Are there any special considerations to make when installing forged valves in distant or environmentally sensitive places?

Indeed, there are extra factors to consider when installing forged valves in remote or environmentally sensitive places. Use of corrosion-resistant materials, compliance with local laws, and environmental impact assessments are essential. Furthermore, setting suitable emergency response plans and monitoring systems can improve environmental protection and safety in these places.

Conclusion

Forged valves are essential to ensuring safety and adhering to industry regulations in natural gas distribution networks. Forged valves are produced using a unique technique that yields parts with exceptional strength, toughness, and resilience to challenging working environments. Because of these characteristics, forged valves are crucial for averting mishaps, guaranteeing the dependability of natural gas supply, and satisfying the strict specifications established by regulatory bodies. As the demand for natural gas continues to grow, the industry must remain vigilant in upholding the highest safety standards. Investing in quality forged valves that comply with industry regulations is essential to building and maintaining a resilient natural gas distribution infrastructure. By prioritising safety and adherence to standards, we can ensure a reliable and sustainable natural gas supply for generations to come.

Since its founding in 1982, Steelstrong Valves has grown to become a well-known manufacturer of valves, with two production sites located in Sanand, Gujarat, and Navi Mumbai, Maharashtra. The company is involved in various activities, including the design, procurement of materials, manufacture, assembly, and testing of valves. A variety of standards (ASME-ANSI, API, BS) are followed in the production of their Gate, Globe, Check, Ball, and Cryogenic Valves, which are available in a range of sizes, pressure ratings, and materials, including Carbon Steel, Alloy Steel, Stainless Steel, Duplex, and Monel. With more than thirty years of expertise in the valve business, Steelstrong Valves is committed to improving the quality management system and customer satisfaction.