Introduction

Precision flow control and system safety are essential in fluid management, especially in sectors that depend on fuel oil systems. Ball valves mounted on trunnions have become necessary to achieve these goals. In this blog, we will examine the significance of trunnion-mounted ball valves in fuel oil systems, emphasizing how important they are for effective flow control and system security.

The Fundamentals of Ball Valves Mounted on Trunnions

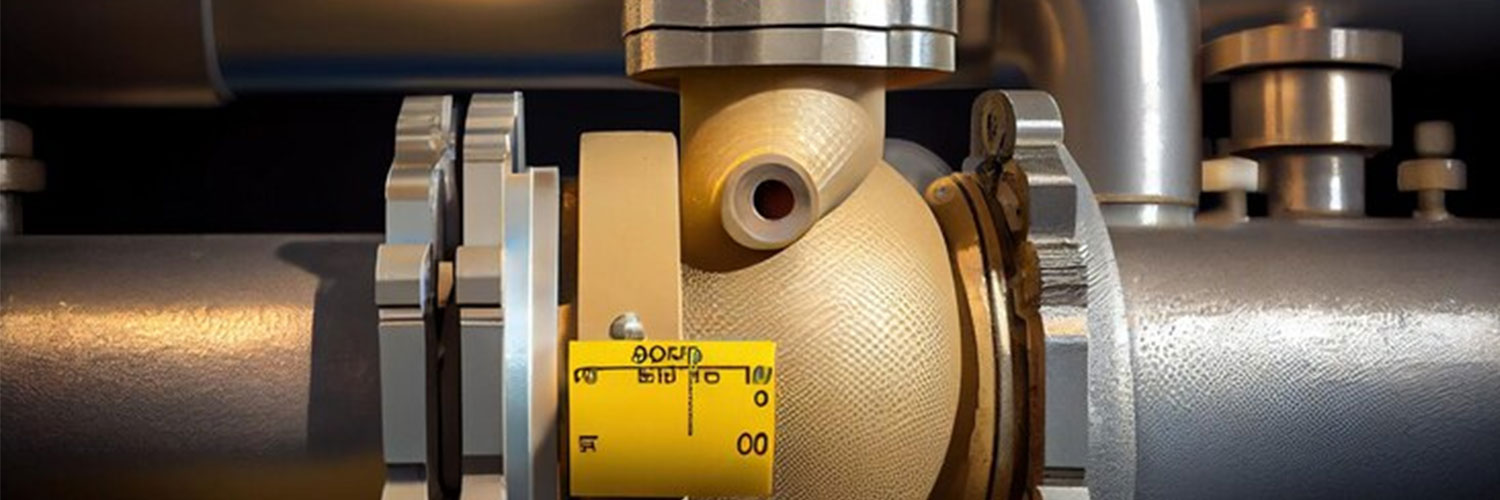

Trunnion-mounted ball valves are made of a hollow ball with a hole (the “ball”). A trunnion-mounted ball valve is a type of industrial valve used to control the flow of fluids, including fuel oil, in a piping system. It gets its name from the trunnion, a fixed pivot point supporting the ball inside the valve. This design provides improved stability and control, making it suitable for high-pressure and high-flow applications. When the valve opens, the hole lines up with the pipe, allowing fluid to pass through. In contrast, when the ball is in the closed position, it rotates and obstructs the flow path.

The support system for the ball is referred to as being “trunnion mounted.” Trunnions or shafts provide additional mechanical support for trunnion-mounted ball valves instead of floating ball valves, which depend on the fluid’s pressure to seal the valve. They are appropriate for situations that call for high-pressure or high-flow control since this design offers more stability.

Efficient Flow Control

Precise Control: Trunnion-mounted ball valves provide accurate flow control for fluids. They are appropriate for situations where fuel oil flow needs to be regulated to meet particular operational requirements because their design enables precise modulation of flow rates.

Low Torque Operation: These valves often require less torque to actuate than other valves, making them more energy-efficient and simpler to use. Low torque operation is especially crucial for systems that require frequent modifications.

Bi-Directional Sealing: Trunnion-mounted ball valves have a “bi-directional sealing” feature, which allows them to restrict flow in both directions efficiently. This attribute is essential in fuel oil systems because tight seals and leak prevention are essential for efficiency and safety.

Systems Safety and Security

Reliable Shut-Off: A crucial safety characteristic in any fuel oil system is the capacity to stop the flow of fuel oil consistently. Ball valves placed on trunnions perform very well in this area due to their durable construction and sealing ability. The valves can be swiftly closed to separate system components during emergencies or scheduled maintenance.

High Pressure Handling: Fuel oil systems frequently work under high pressure. As their trunnion-mounted ball design assures stable functioning even under tremendous pressure, trunnion-mounted ball valves are well suited for such circumstances and lower the chance of valve failure.

Durability and Longevity: Valves endure a lot of stress in industrial situations. Ball valves placed on trunnions are renowned for their dependability and lifespan, which lowers the frequency of replacement and maintenance requirements. Fuel oil systems’ safety and continuous operation largely depend on this reliability.

Conclusion

Ball valves installed on trunnions are essential for fuel oil systems because they improve system safety and enable effective flow management. In these crucial applications, their precision, low torque operation, bi-directional sealing, and capacity for high pressures make them essential components. Trunnion-mounted ball valves are critical in preserving system integrity and safety as long as industries rely on fuel oil systems. Trunnion-mounted ball valves are undoubtedly a top option for customers looking for control and peace of mind in their fuel oil systems. Choosing the appropriate valve for your particular application is essential.

FAQs

Q1: How do ball valves installed on trunnions improve system security in fuel oil applications?

A: Ball valves installed on trunnions improve safety by offering dependable flow control and reducing the possibility of gasoline leaks or spills. They are also appropriate for emergency shutdown applications, which helps avoid mishaps or system overpressure.

Q2: What aspects must you consider when choosing trunnion-mounted ball valves for fuel oil systems?

A: While choosing a trunnion ball valve, you should consider the following aspects:

- Pressure and temperature requirements are among the variables to take into account

- Valve and bore dimensions

- Compatibility of the materials with the fuel oil

- Control of flow specifications

- Environmental factors, such as exposure to the outdoors.

Q3: Can trunnion-mounted ball valves be automated for remote control?

A: Electric or pneumatic actuators can automate trunnion-mounted ball valves. This automation makes integrating the valve into fuel oil systems simpler with sophisticated control needs since it enables remote control and monitoring of the valve.

Q4: What are the commonly used materials in constructing trunnion-mounted ball valves for fuel oil systems?

A: The construction materials for trunnion-mounted ball valves used in fuel oil systems depend on the particular specifications of the application. Stainless steel, carbon steel, and uncommon alloys like duplex and super duplex stainless steel, which provide corrosion resistance and endurance, are widespread.

Q5: How can I ensure the proper maintenance of trunnion-mounted ball valves in a fuel oil system to ensure system safety?

A: Trunnion-mounted ball valves in fuel oil systems require regular maintenance to be effective and safe. Routine inspection, lubrication, and leak testing are among the maintenance procedures. It’s crucial to adhere to the manufacturer’s recommendations and plan maintenance according to your system’s particular operating circumstances and demands. Hiring a professional and trained technician to undertake maintenance is also advisable.

Q6: Can onshore and offshore fuel oil applications employ trunnion-mounted ball valves?

A: It is possible to design and build trunnion-mounted ball valves to satisfy the needs of both onshore and offshore fuel oil systems, taking into account things like corrosion resistance and subsea installation requirements.

Q7: What are some typical problems with fuel oil systems’ trunnion-mounted ball valves?

A: Difficulties could include preserving proper sealing over time, avoiding valve fouling from fuel oil contaminants, and ensuring compatibility with the particular fuel oil composition. Always consult with valve manufacturers like Steelstrong, and industry experts to ensure the proper selection, installation, and maintenance of trunnion-mounted ball valves for your fuel oil system and maximize flow control and system safety.